- Our Services

- Advanced Fuel Nozzle Manufacturing for Gas Turbine Applications

Advanced Fuel Nozzle Manufacturing for Gas Turbine Applications

Thorough inspections by expert technicians to enhance the reliability and efficiency of your generators

Advanced Fuel Nozzle Manufacturing for Gas Turbine Applications

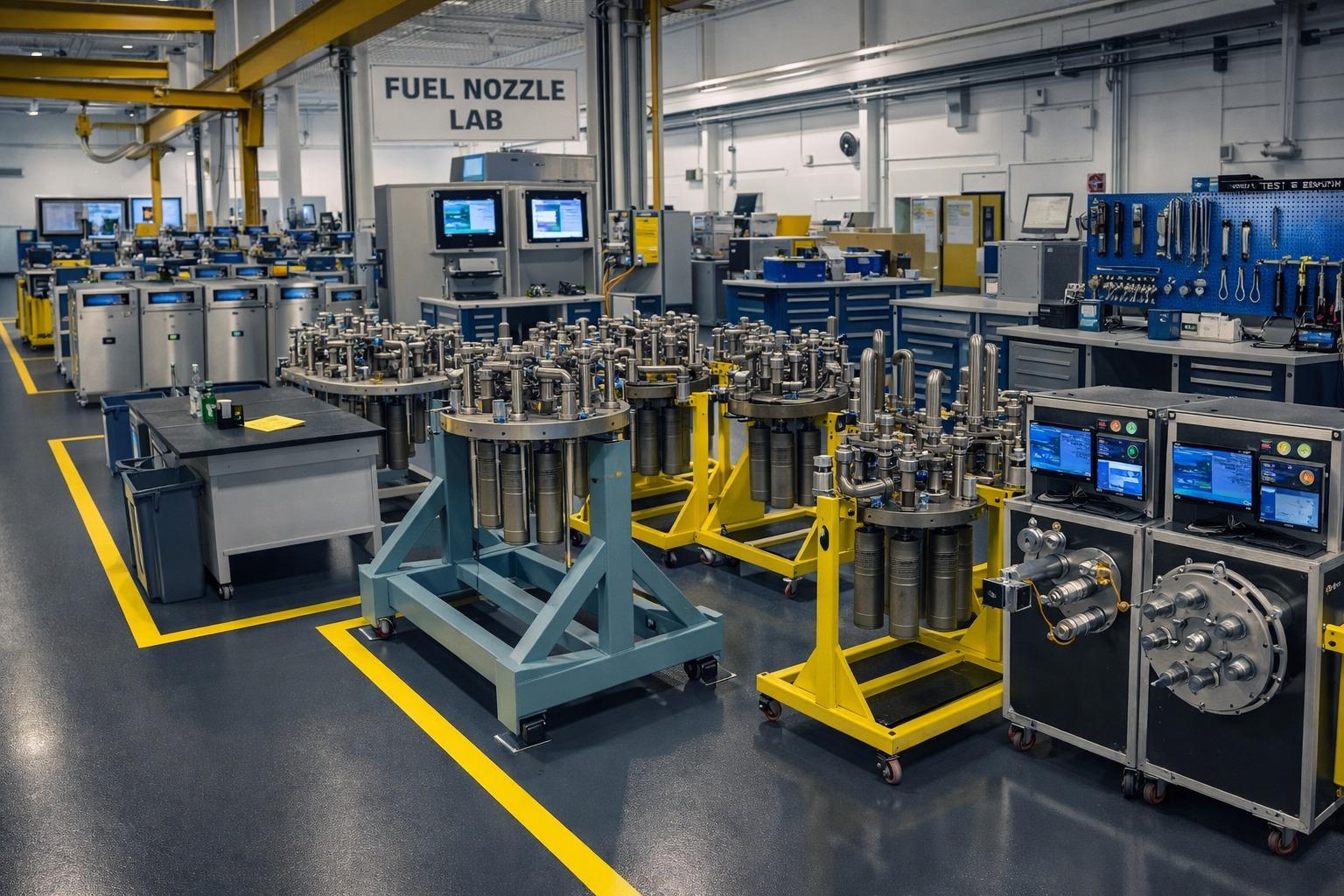

Advanced manufacturing and supply of high-performance fuel nozzles for all major OEM gas turbines, covering both heavy-duty and aero-derivative platforms. Each component is developed using a purpose-engineered approach, combining application-specific design with precision manufacturing to meet the most demanding operating conditions.

Fuel nozzles are manufactured using a range of advanced casting technologies, including conventional casting as well as single-crystal (SX) solutions where required by the application. This flexibility enables optimal material selection based on thermal loads, mechanical stresses, and lifecycle expectations, ensuring reliability and long-term performance in extreme combustion environments.

Critical geometries are produced to tight tolerances to achieve stable combustion, optimal fuel atomization, and controlled emissions across a wide operating range. All designs are supported by engineered flow characteristics, validated through dedicated flow test benches capable of replicating real gas turbine operating conditions, ensuring consistency, repeatability, and full compliance with OEM requirements.

From casting and precision machining to assembly and final validation, every fuel nozzle is developed with a fit-for-purpose engineering philosophy. Solutions support both new production and aftermarket applications, delivering dependable performance for power generation and aero gas turbine systems while meeting international quality and certification standards.